THIS PROCEDURE MUST BE PERFORMED BY A QUALIFIED TECHNICIAN.

CAUTION

CAUTION

FREEZE PROTECTION: Risk of frozen pipes. Can cause property damage. Hydronic heating system freeze-ups WILL cause extensive damage to the entire heating system and/or property. It is the responsibility of the installer to provide protection against freezing.

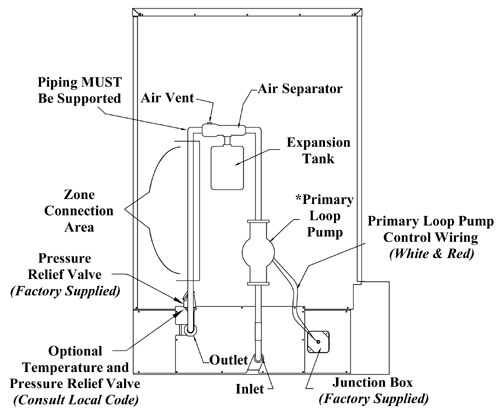

PIPING SUPPORT: Risk of exchanger damage. Can cause property damage or personal injury. DO NOT use the exchanger as support for piping. Support brackets should be in place to ensure proper operation of the system and to keep pressure off the inlet and outlet piping.

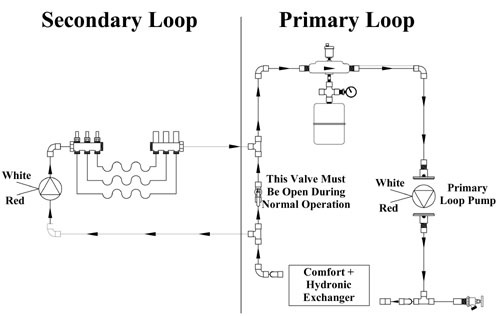

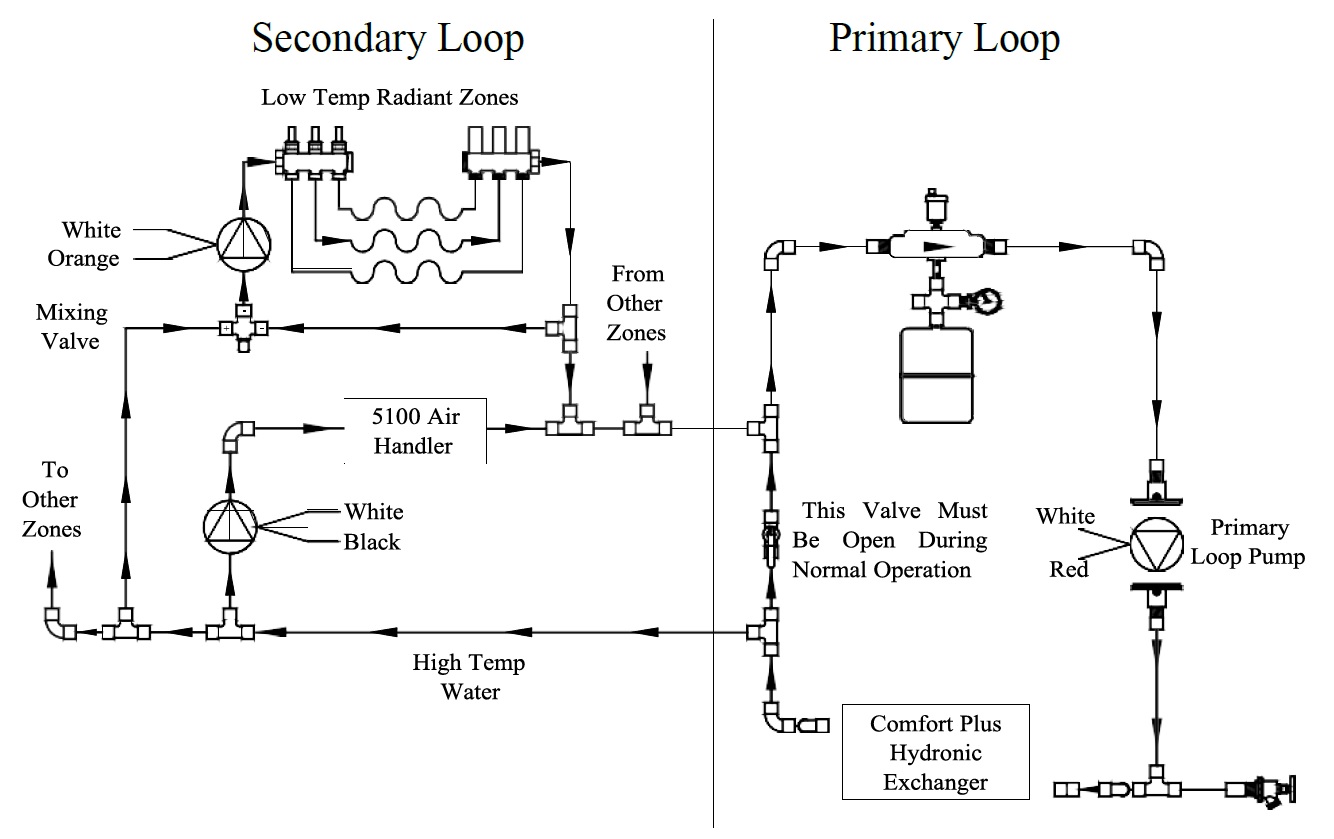

It is the responsibility of the installer to prevent involuntary flow of water to the air handler. Not doing so may cause limit tripping and/or decrease heat pump efficiency. Use of a check valve, zone valve, or other device may help prevent involuntary flow.