THIS PROCEDURE MUST BE PERFORMED BY A QUALIFIED TECHNICIAN.

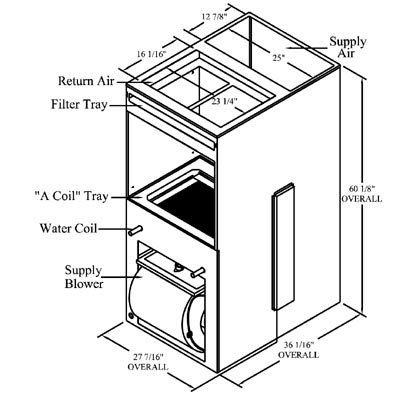

The Steffes ¾ HP Air Handler is an optional device used to interface the Comfort Plus Hydronic with a centrally ducted heating or cooling system. The Air Handler includes a plenum assembly, supply air blower, water coil, air filter, wiring harness, and hardware kit.

OPERATION

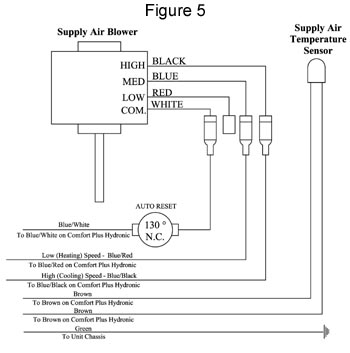

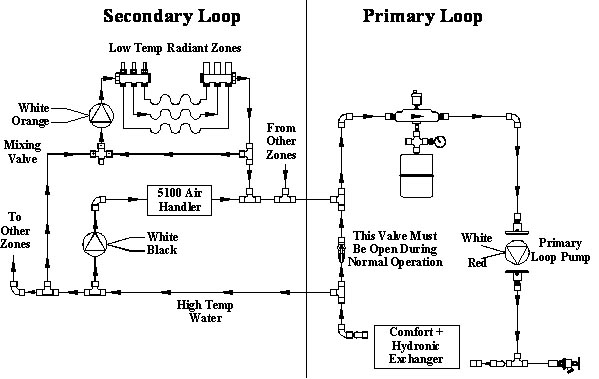

When the Comfort Plus Hydronic system receives a heat call from the air handler’s room thermostat, the primary loop pump (circulator) is energized to circulate water through the heat exchanger. At the same time, the air handler’s pump (circulator) and the supply air blower are energized. The pump circulates the hot water through the air handler’s water coil and the supply air blower extracts the heat from the water in the coil and delivers it to the appropriate heating zone through the ductwork. When connected directly to the Comfort Plus Hydronic system, the air handler also directs heat lost statically into the living space providing automatic static heat recovery. If used with a heat pump, the air handler has the ability to monitor the outlet air temperature and provide comfort modulation as needed.

SPECIFICATIONS

|

Specification |

Value |

|---|---|

|

Maximum Outlet Temperature |

120°F |

|

Maximum Static Pressure |

.75 inches H2O |

|

Maximum Water Coil Output |

80,000 BTU/hr |

|

Maximum A-Coil Size - Front Access |

25.4"W X 22.25"H X 21.2"D |

|

Inner Dimensions of A-Coil Area |

26.4"W X 24.5"H X 21.2"D |

|

Voltage |

240/208 VAC |

|

Wattage |

1,300 |

|

Supply Air Blower |

3/4 HP, 60 HZ |

WARNING

HAZARDOUS VOLTAGE: Risk of electric shock. Can cause injury or death. Disconnect all remote electric power supplies before installing and/or servicing.

HIGH TEMPERATURES: Risk of burn. Can cause personal injury. Do not install air handler when outer surfaces of the system are hot.

INSTALLATION

De-energize System

De-energize the Comfort Plus Hydronic system and unbox the Air Handler.

Remove Supply Blower Cover

Remove cover from the supply blower opening (Figure 1) of the Air Handler and locate the hardware kit.

Figure 1:

Remove Coil and Filter Covers

Remove coil and filter covers. Then, remove the water coil access panel of the Air Handler.

Remove Screw and Position the Coil in Place

During shipping, the water coil is held in place by one screw on the right side panel of the Air Handler. Remove the screw and lower the water coil into place. Secure the water coil and the A-coil tray with the screws provided in the hardware kit.

Replace Screws

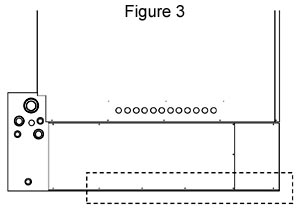

Replace the five bottom, back screws on the right side of the Comfort Plus Hydronic system with five of the 7/8” screws provided in the hardware kit (Figure 3).

NOTE: Do NOT run the new screws all the way in. They should remain out about 3/8”.

Attach Air Handler

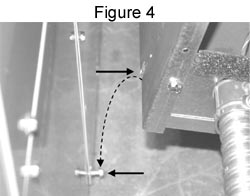

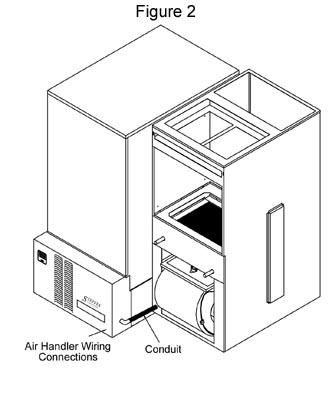

Tilt the Air Handler and set it onto the screws protruding from the right side of the Comfort Plus Hydronic system (Figure 4). Attach the Air Handler to the right side of the Comfort Plus Hydronic system using screws provided in the hardware kit. Refer to Figure 2 for placement of the Air Handler in relation to the Comfort Plus Hydronic system.

Remove Knockouts

Remove the two knockouts on the water coil access panel and attach it to the Air Handler.