Part 22 Description - 4100 Series

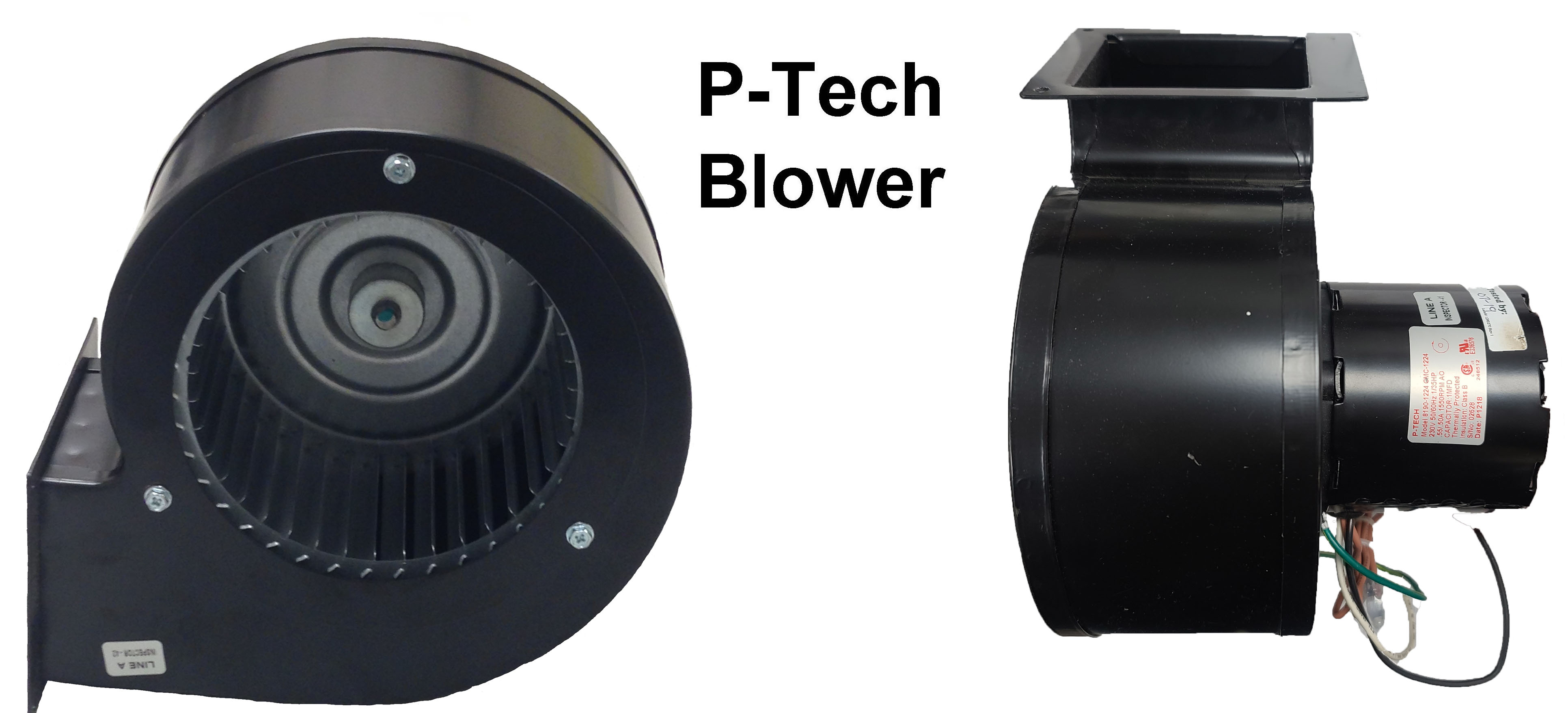

Core Blower

When the system receives a heat call, the supply air blower is energized and circulates air through the duct system and into the home. The discharge air sensor monitors the discharge air temperature. If the discharge air temperature (as set in L048 and L049) is not being reached, the core blower(s) is energized and circulates air through the brick core. This heated air is mixed with the return air to maintain the desired temperature. If the front air channel is not installed properly, the core blowers will operate; however, will be unable to extract heat from the brick core.

All 4100 Series systems have two core blowers. If only one of the core blowers is needed to maintain the desired discharge air temperature, then the system will automatically alternate between the two blowers as needed. The core blower speed is determined by the amount of voltage sent to each blower from the base I/O relay board. As the fan speed requirements increase, voltage to the blower(s) increases. Refer to Location 112 (L112) for the current discharge air temperature and Locations 120 and 121 (L120 and L121) for core blower speeds. Check voltage AC from the L2 terminal to blower and damper terminals on the base I/O relay board and compare this reading to the Blower/Damper Activation Chart.

Early blower motors had sleeve type bearings that were permanently lubricated. Steffes does not recommend oiling these motors; however, if desired, a motor can be re-oiled with SAE 20 oil. Over oiling the motor can cause motor failure! Later blowers were equipped with ball bearings. These motors are not intended to be lubricated.

Vibration of the blower can be caused by a build up of dirt and debris. If there is a noise issue, clean the blower wheel and verify that the blower is mounted properly. All motor windings must have at least 20 meg ohms of resistance from each of the leads to ground. Resistance across the motor leads should be as shown in the tables below.

|

Motor Resistance (ohms / Ω) |

||

|---|---|---|

|

Date |

Type |

240V |

|

Before 2007 |

Fasco |

60-75 |

|

PTech Multi-Tap |

160-210 |

|

|

After 2007 (see bottom of page for details) |

Fasco |

60-75 |

|

PTech 240V |

175-225 |

|

|

PTech Multi-Tap |

160-210 |

|

For more information on troubleshooting the core blower, replacing a core blower, or ordering replacement parts, refer to the links below:

Links:

NOTE: The 2nd and 3rd digits of the serial number indicate the month, while the 4th and 5th digits represent the year the Steffes heating system was manufactured. As the break-in began in January of 2007, any 4100's built in 2007 or later will require Part #1021035R.

-

Before SN: 201074328013484, use part number 1021037R-240:

-

After SN: 201074328013484, use part number 1021035R: