THIS PROCEDURE MUST BE PERFORMED BY A QUALIFIED TECHNICIAN.

-

Turn power on to the transceiver.

-

Look at LED-L3. It should blink OFF-and-ON slowly then increasingly faster until it locks ON indicating it has received PLC signal from the transmitter.

NOTE: It can take 2-3 minutes for PLC signal reception when using a “fast” channel and 7-10 minutes when using a “slow” channel.

-

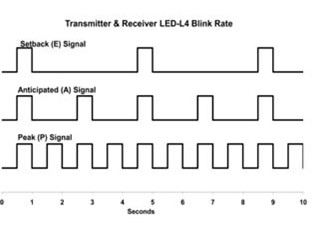

Look at LED-L4, (2). It may be:

-

OFF when receiving an off-peak signal

-

ON solid if an override switch is enabled

-

blinking OFF and ON according to the type of signal being received from the control device.

-

-

Simulate an off-peak period at the transmitting device.

-

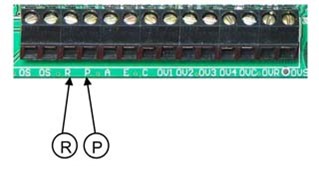

If DIP switch #1 is in the ON position at the transmitting device, this can be done by placing a jumper wire across the R and P terminals.

-

If DIP switch #1 is in the OFF position at the transmitting device, an open across R and P will simulate the off-peak period.

-

LED 4 should be OFF.

-

The relay LED’s should all be ON.

-

Go to each controlled load (appliance) and make sure it is operating.

-

-

-

Simulate a peak period at the transmitting device.

-

If DIP switch #1 is in the OFF position at the transmitting device, this can be done by placing a jumper wire across the R and P terminals.

-

If DIP switch #1 is in the ON position at the transmitting device, an open across R and P will simulate the peak period.

-

Look at the relay LED’s. They should all be off.

-

Look at LED-L4. It should be blinking at the peak rate as shown.

-

If one of the optional overrides has been installed, verify proper operation of the override device.

-

-

NOTE: When checkout is complete, make sure:

-

DIP switches are all set to the proper position.

-

Jumper wire has been removed.

-

All wiring connections are tight.